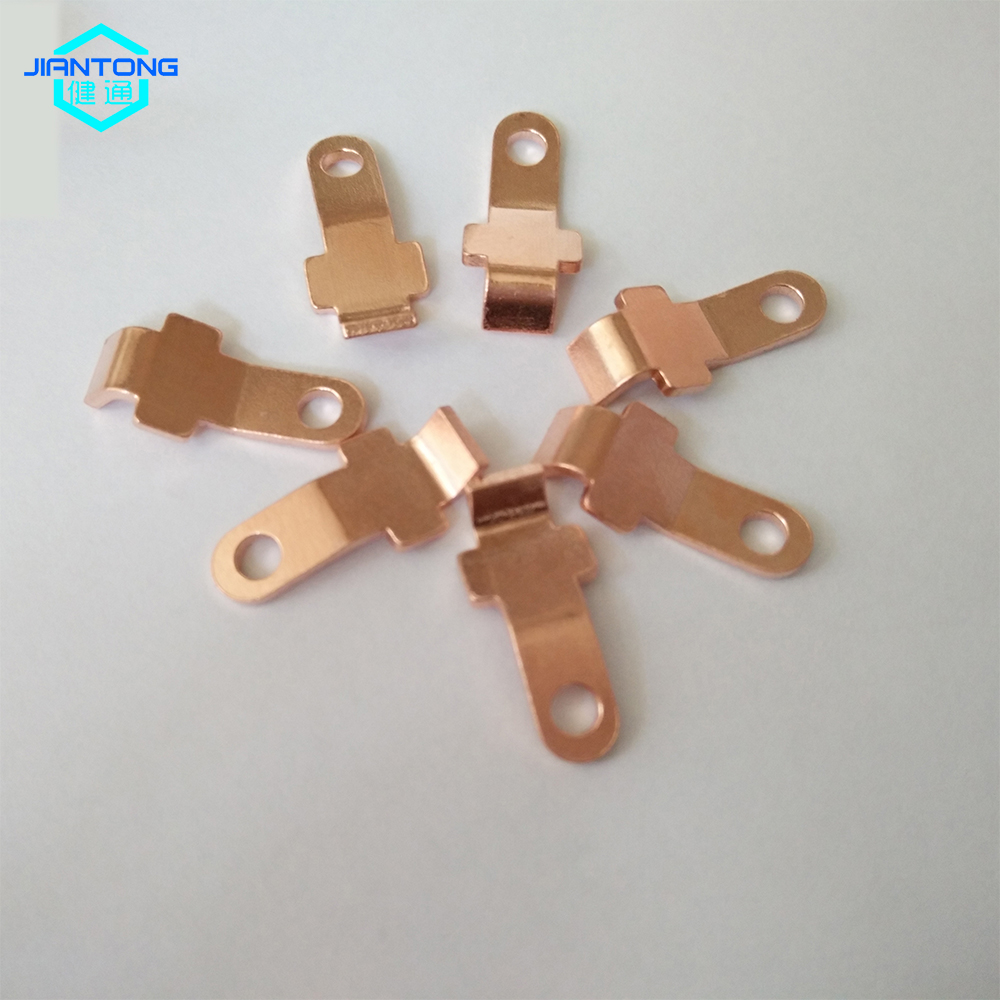

Custom Wire Connector Copper Stamped Metal Pressing Parts

The purpose of the Metal Stamping forming process is to plastically deform the sheet without breaking the blank to produce a workpiece of the desired shape and size

| Product Name | Custom Wire Connector Copper Stamped Metal Pressing Parts

|

| Material | Brass, Copper, Carbon Steel, Stainless steel, steel alloy, Aluminum alloy |

| Surface treatments | Customized Small Metal Parts Metal Laser Cutting Service |

| Processing | Custom Wire Connector Copper Stamped Metal Pressing Parts |

| Heat treatment capability | Annealing, Normalizing, Nitriding, Tempering, Carbonitriding, Carburizing and induction hardening |

| Processing machine | Automatic lathe machine, Stamping lathes, Milling/Grinding machine, Drilling/Boring/Honing machine, Ultrasonic cleaning machine and other advanced production equipments. |

| Inspection machine | Projector, Caliper, Universal testing, machine, Surfagauge and screw gague |

| Packing | Standard export carton pallet or as requirement |

| Shipping | Within 7 days after deposit received (depends on the quantity) |

| Application | Vehicle, Car, Electronic components, Household, Hardware, etc. |

Brass Stamping is a method of forming a workpiece (stamping part) of a desired shape and size by applying an external force to a plate, a strip, a pipe, a profile, and the like by a press and a die to cause plastic deformation or separation. Stamping and forging are the same plastic processing (or pressure processing), collectively called forging. The stamped blanks are mainly hot rolled and cold rolled steel sheets and strips. Of the world's steel, 60 to 70% are sheets, most of which are stamped into finished products. The body, chassis, fuel tank, radiator plate of the automobile, the steam drum of the boiler, the casing of the container, the iron core silicon steel sheet of the motor and the electric appliance are all stamped and processed. There are also a large number of Stamping Parts in instruments, household appliances, bicycles, office machinery, living utensils and other products.

Stamping processing is the production technology of product parts that are deformed and deformed directly in the mold by means of the power of conventional or special stamping equipment to obtain a certain shape, size and performance. Sheets, molds and equipment are the three elements of stamping. According to the stamping processing temperature, it is divided into hot stamping and cold stamping. The former is suitable for sheet processing with high deformation resistance and poor plasticity; the latter is carried out at room temperature, which is a common stamping method for thin sheets. It is one of the main methods of metal plastic processing (or pressure processing) and is also part of material forming engineering technology.

The mold used for stamping is called a stamping die, or a die for short. Dies are special tools for batch processing materials (metal or non-metal) into the required punches. Dies are very important in stamping. There are no dies that meet the requirements. Batch stamping production is difficult to carry out; without advanced dies, advanced stamping processes cannot be realized. The stamping process and the mold, stamping equipment and stamping materials constitute the three elements of stamping processing, and only when they are combined with each other can the stamping parts be obtained.

At Jiantong Hardware, we combine our core values of listening, providing dependability, and our dedication to top-quality to continually give our customers confidence. We call that kind of confidence Power Satisfaction and we`re proud to manufacture that into every part we make.

Nanpi Jiantong Hardware Manufacturing Co., Ltd is a designer and manufacturer for Custom Sheet Metal Stamping Partsand Custom Wire Connector Copper Stamped Metal Pressing Parts. Whether you require metal stampings, metal forming and sheet metal fabrications, tooling and die programming or Custom Cnc Parts,Sheet Metal Cutting Bending Welding Parts Metal Fabrications , Metal Fabrication,metal stamping and welding and other services we provide, the expert team will ensure first-class service and high-grade quality, backed by our ISO 9001:2008 and TS16949 Quality Assurance guarantee. Please send your Enquiries here and Contact us for considerate services.

We are factory, the direct source to keep the prices for precision metal stamping at low by eliminating the middleman. It saves at least 25% in metal stamping.

Controlling the material costs as well as in the process of production, we offer you unsurpassed quality without any costly material markups and delivery delays.

Contact: